Chimney Repair Systems

|

HeatShield® Restores Your Chimney

HeatShield® is a specially formulated “Cerfractory®” sealant material that restores the integrity of your chimney’s flue to vent hazardous flue gases from your home. It eliminates the dangers in your chimney caused by gaps, cracks, and spalling for years to come. By using either the Repair System or the CeCure® Sleeve Relining System (depending on the defects found) your chimney will be restored to its original peak level of safety and efficiency. Joint Repair To repair chimney interiors, one of two methods are used. The Joint Repair System is used for chimneys that only require repair of defective mortar joints. The Resurfacing System is used to repair mortar joints and other minor defects in tile lined flues. |

With our (patent pending) Joint Repair system your chimney is fixed right, the first time.

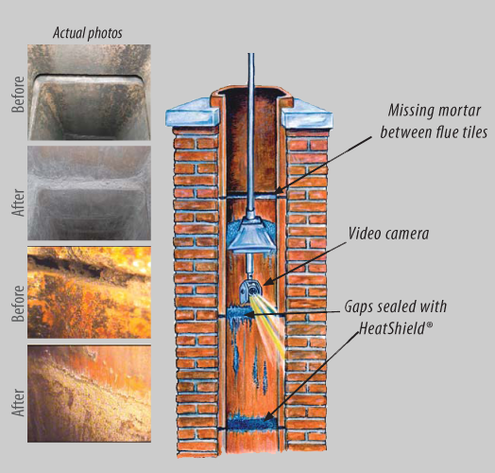

First, a special foam applicator blade is custom made to fit your chimney. The applicator tool and blade are then plunged down your chimney and positioned below each gap or void.

The HeatShield® Cerfractory® Flue Sealant mixture is added. Each void in your flue is filled as HeatShield® mixture is extruded into the void by the tool. Your repaired void is then made smooth as the blade passes over the filled void as the tool is pulled upward.

Your repair is then immediately scanned with a specially designed video camera attached to the bottom of the tool. Your professional HeatShield® Installer then verifies that each gap or void has been properly repaired as it is immediately viewed on the cameras monitor.

First, a special foam applicator blade is custom made to fit your chimney. The applicator tool and blade are then plunged down your chimney and positioned below each gap or void.

The HeatShield® Cerfractory® Flue Sealant mixture is added. Each void in your flue is filled as HeatShield® mixture is extruded into the void by the tool. Your repaired void is then made smooth as the blade passes over the filled void as the tool is pulled upward.

Your repair is then immediately scanned with a specially designed video camera attached to the bottom of the tool. Your professional HeatShield® Installer then verifies that each gap or void has been properly repaired as it is immediately viewed on the cameras monitor.

Resurfacing System

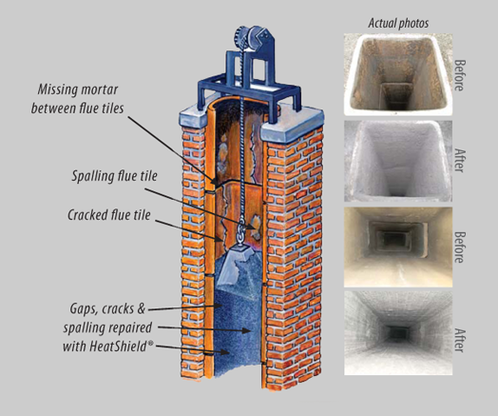

For chimneys with cracked or spalled flues that are otherwise sound, the Resurfacing System

is used to apply a coating over the entire flue. Cameras are used to verify repairs.

To restore your chimney’s flue by resurfacing the interior, a custom made foam applicator plug is placed at the bottom of the flue and attached to a winch on top the chimney.

First, a “tie coat” material is applied to the flue walls as the plug is pulled upward by the winch. The “tie coat” cleans any remaining dust in your flue and acts as a primer for the HeatShield® Cerfractory® Flue Sealant.

After the tie coat dries, the HeatShield® material is then applied onto the flue at a thickness of about ¼” with the foam plug as it is pulled upward by the winch. This unique application method is known as “slip casting” or “slip cast extrusion”.

Your professional HeatShield® Installer then verifies that your newly restored chimney is completely sealed and smoke-tight by video scanning your completed repair.

First, a “tie coat” material is applied to the flue walls as the plug is pulled upward by the winch. The “tie coat” cleans any remaining dust in your flue and acts as a primer for the HeatShield® Cerfractory® Flue Sealant.

After the tie coat dries, the HeatShield® material is then applied onto the flue at a thickness of about ¼” with the foam plug as it is pulled upward by the winch. This unique application method is known as “slip casting” or “slip cast extrusion”.

Your professional HeatShield® Installer then verifies that your newly restored chimney is completely sealed and smoke-tight by video scanning your completed repair.

Reline with a Stainless Steel Liner

In some cases the HEAT SHIELD system isn't a viable option. For those cases we recommend a Stainless Steel Liner

Metal chimney liners, usually of stainless steel or aluminum, are primarily used to upgrade and repair existing chimneys. These liner systems are U.L. tested and listed, and if properly installed and maintained are extremely safe and durable. Stainless steel is suitable for woodburning, gas, or oil applications, while the aluminum is an inexpensive alternative for certain medium efficiency gas applications only. It is usually required that high temperature insulation be used in conjunction with the liners for safety and performance considerations. - See more at: http://www.csia.org/homeowner-resources/about_chimney_liners.aspx#sthash.ADYZIrSv.dpuf